Galvanizing Steel for Life

With over 150 years of expertise

Working Across all Sectors

Wedge Group galvanizing have knowledge and expertise of working across many sectors.

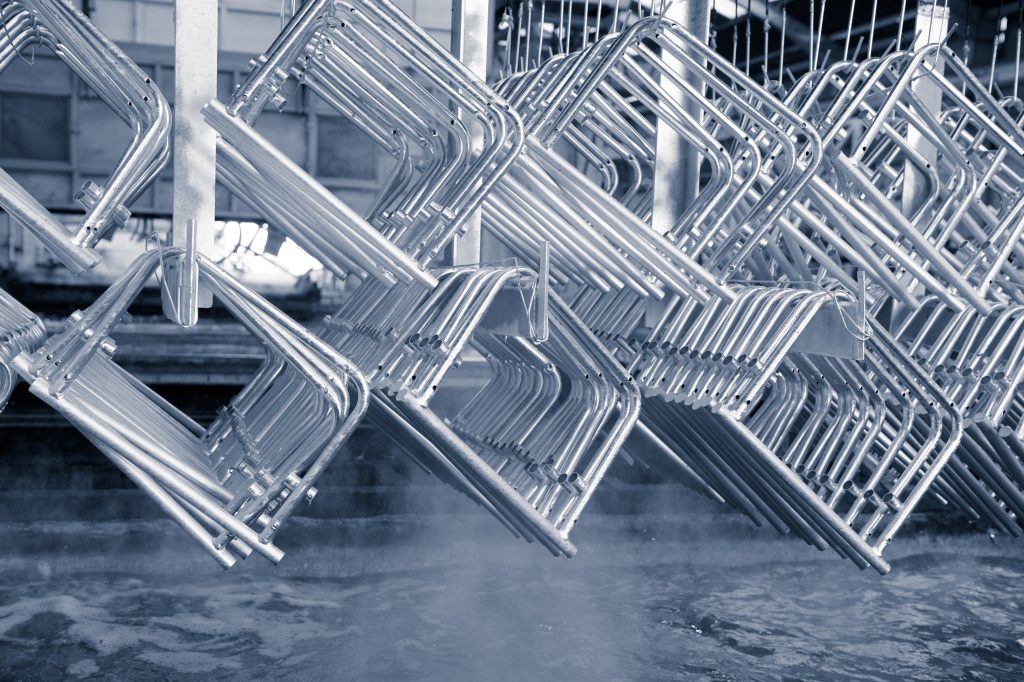

Hot Dip Galvanizing, with its winning combination of long-lasting protection, ease of application and sustainability, is the finish of choice for many industries across the globe including; construction, manufacturing, infrastructure and agriculture.

The Benefits of Galvanizing Steel

Hot dip galvanizing has, for many decades, been widely recognised – as well as proven – to be the most effective and reliable way to protect steel from corrosion, providing robust steel corrosion protection in a variety of industries and outdoor environments. Steel galvanized through this method is shielded by a durable zinc coating that extends it’s lifespan significantly.

There are numerous benefits to hot dip galvanizing, the most significant of which is its ability to dramatically extend the lifetime of steel products in a range of environments; particularly important since an estimated 4% of the world’s GDP is lost each year through corrosion.

Galvanizing’s ability to prolong a product’s lifetime make it highly cost-effective, since little or no maintenance is required – giving hot dip galvanizing the lowest overall cost compared to other protective steel coatings.

Sustainability is also a key focus for the galvanizing industry, specifically in terms of recyclability. Hot dip galvanizing produces minimal waste, as any excess zinc will remain in the zinc bath and subsequently be re-used. This is made possible through the non-ferrous properties of the zinc itself which enable it to be reused again and again without any loss of its physical or chemical constitution.

Additionally, because hot dip galvanizing takes place after a product has already been fabricated, the steel is coated with a tough and abrasion-resistant zinc coating both externally and internally. This means the steel product arrives on site ready for immediate use. No further site surface preparation, painting, touch up or inspection is necessary, and installation can begin immediately – thus accelerating the construction time.

Key Stats

14

Plants

Wedge Group Galvanizing are the largest UK galvanizing organisation with 14 plants strategically placed throughout the UK

16

Baths

We have 16 class 1 galvanizing baths throughout our plants which are all lead free

29m

Steel Lengths

We have the largest galvanizing bath in the UK at 21m long – enabling us to galvanize structural steel up to 29m in length. We also have a dedicated spin galvanizing plant.

100

Vehicle Fleet

We have a fleet of over 100 vehicles which can collect and deliver your steel – we can also deliver straight to site.

Latest News From Wedge

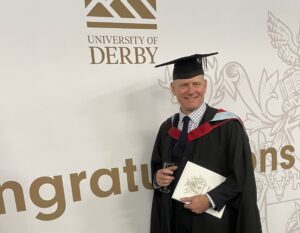

- Wedge Group’s Director Achieves Prestigious Sustainability Qualification

Wedge Group Galvanizing Ltd is proud to announce that David Nobes, one of its senior management team, has successfully completed a rigorous Masters qualification in sustainability – a milestone that’s already delivering tangible results across the business and beyond. Read more Wedge Group’s Director Achieves Prestigious Sustainability Qualification

Wedge Group Galvanizing Ltd is proud to announce that David Nobes, one of its senior management team, has successfully completed a rigorous Masters qualification in sustainability – a milestone that’s already delivering tangible results across the business and beyond. Read more Wedge Group’s Director Achieves Prestigious Sustainability Qualification - Bench of Bravery Built in Honour of Gunner Lee Thornton

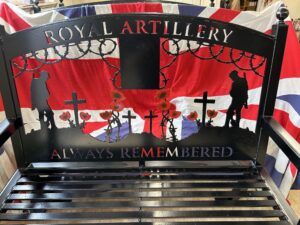

A handcrafted commemorative bench has been installed at the Fylde Memorial Arboretum near Blackpool to honour the life and service of Gunner Lee Thornton. Read more Bench of Bravery Built in Honour of Gunner Lee Thornton

A handcrafted commemorative bench has been installed at the Fylde Memorial Arboretum near Blackpool to honour the life and service of Gunner Lee Thornton. Read more Bench of Bravery Built in Honour of Gunner Lee Thornton - ‘Towneley Flame’: Manchester‑Galvanized Dragon Ignites the Park

Wedge Group Galvanizing’s Manchester plant has played a pivotal role in bringing a spectacular new sculptural dragon to life – and ensuring it will endure as a striking landmark for years to come. Read more ‘Towneley Flame’: Manchester‑Galvanized Dragon Ignites the Park

Wedge Group Galvanizing’s Manchester plant has played a pivotal role in bringing a spectacular new sculptural dragon to life – and ensuring it will endure as a striking landmark for years to come. Read more ‘Towneley Flame’: Manchester‑Galvanized Dragon Ignites the Park

Fastenings

Fastenings  Industrial Plant and Equipment

Industrial Plant and Equipment  Storage and Handling

Storage and Handling  Transport Infrastructure

Transport Infrastructure  Street and Outdoor Furniture

Street and Outdoor Furniture  Construction

Construction  Art and Sculpture

Art and Sculpture  Agriculture

Agriculture